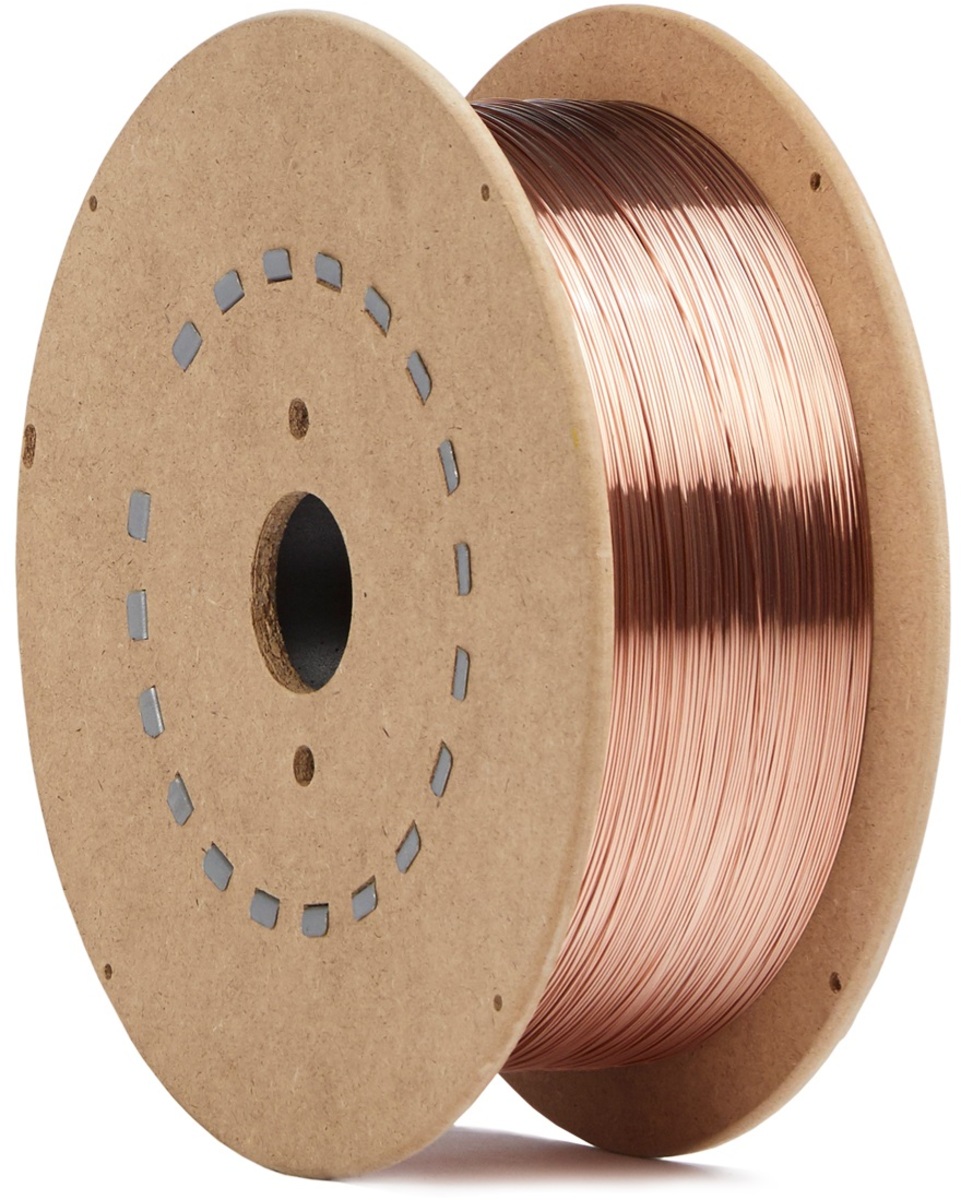

0.035" ER70S-3 ARC® NS101US Copper-Glide™ Copper Alloy MIG Wire 45 lb 11.75" Spool

Airgas Part #:NAT4050317

Manufacturer Part #:4050317

Log in to get your price

$5.98

US Pound

$5.98

/US Pound

Item Details

- NS ARC™ NS101US Copper-Glide™ .035 carbon steel copper-coated MIG welding wire 45LB Spool Made in USA ER70S-3, EM13K.

Features

- NS-101 Copper-Glide™ is a premium copper-coated mild steel solid filler wire designed to extract maximum weld quality and user appeal from ER70S-3 wire

- The manganese and silicon contents are restricted to the high end of the chemistry range, assuring maximum deoxidation, flat bead profiles and low spatter levels.

Specifications

- AWS A5.18: ER70S-3

- AWS A5.17: EM13K

- ASME SFA-5.18: ER70S-3

- MIL-E-23765/1: MIL-70S-3

- CWB W48: B-G 49A 2 C1 S3

- ABS ER70S-3

Applications

- It supports all metal transfer modes of GMAW and is compatible with robotic, mechanized, and semi-automatic welding.

- It's the ideal choice for use in the automotive, transportation, energy, and manufacturing industries.

- This type of welding wire also can be used for applications that require a minimum of 70,000 psi of tensile strength.

Product Attributes

Trade Name

» NS ARC® NS101US Copper-Glide™AWS Classification

» ER70S-3» EM13K

Diameter

» .035"Weight

» 45 lbSpool Diameter

» 11.75"